Kingfield Technologies & Equipment

HAVE CONFIDENCE WITH KNOWLEDGE YOU CAN TRUST

Kingfield Technologies & Equipment

More than 35 years of experience

Kingfield Technologies & Equipment Pty Ltd (KTE) has more than 35 years of experience in the Hot Dip Galvanizing industry and now lists among its clients more than 60 major galvanizing plants in Australia, New Zealand, South East Asia, China and the Middle East.

Our wealth of experience means that every galvanizing plant requirement can be supplied with the most up to date Design, Engineering Systems and Technical Services.

Reflecting excellence in the areas of design, construction, installation and training, KTE has won the Australian Galvanizing Industry Sorel Award for Industrial Innovation and Excellence four times. When we design and engineer galvanizing infrastructure our clients feel confident that we do this with a successful history of industry experience.

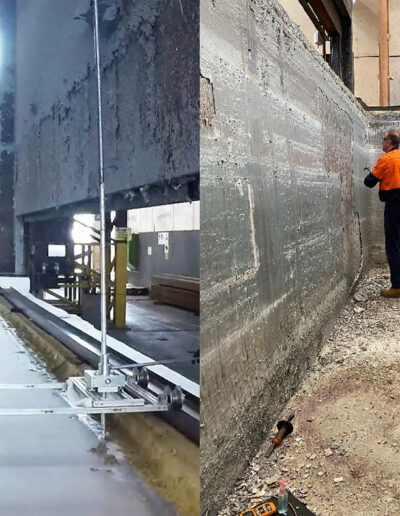

Projects

Great projects don’t just happen. They require planning, attention to detail, the best available technology and equipment for the funds available and highly skilled, motivated and experienced staff. Kingfield Technologies and Equipment has been delivering great projects for many years. We focus on our clients needs and ensure the projects deliver success.

Products

Identifying and installing the “right” equipment package for a new or refurbished galvanizing facility is critical to its long-term success. We understand operating requirements and budget constraints and work with our clients to provide the best possible solution. Many years of experience across a very wide range of galvanizing facilities ensures we understand what is best in the circumstances.

Operations & Production Services

Installation is only the beginning of the plant success story. On-going monitoring, maintenance and service are critical to long term success. We provide a range of services to ensure our client’s galvanizing plants are able to maintain production and productivity and to be operated at maximum profitability for the long term.

Global Footprint

With offices in Australia, Singapore, Indonesia and United Kingdom and clients in more than a dozen countries we are experienced in handling projects and service requirements throughout the world.

Energy & Environment

The high and increasing costs of energy and the requirements to minimise the environmental impact of galvanizing processing have become critical factors in the design and operation of galvanizing plants. We can provide the latest in the design, installation and even retrofitting of solutions to these critical factors.

![]()

![]()

Testimonials

Secure Client Portal Access

Every client of Kingfield Technologies and Equipment enjoys the benefit of their own secure portal access. This is a no charge benefit providing 24/7 access to:

- Parts ordering and requests for quotations (including photos and part details)

- Client site specific resources (electrical drawings, manuals, service reports etc)

- General resources (training manuals, how to manuals, videos, industry contacts, education items and similar resources)

Access to this information (onsite or offsite) from virtually any device is an invaluable time saving benefit reserved exclusively for the clients of KTE.

Communications

Kingfield Equipment has more than 30 years of experience in the galvanizing industry and now lists among its clients 52 major galvanizing plants in Australasia and the Middle East. This wealth of experience means that every galvanizing plant requirement you have can be supplied with the most up to date Engineering Systems and Technical Service.

KTE Updates – Zinc Metal Recycling

A hard to beat investment Hard to argue against an investment that conserves resources and provides a 6 to 12 month Return on Investment - and then provides tens of thousands of $$$ savings for years to come.The Reclaimer King Furnace is designed to reclaim zinc metal...

KTE Updates – Full Furnace Upgrade

High corrosion rates impact furnace efficiency Recent works undertaken for our client have seen a full furnace upgrade to replace their existing furnace components. Older galvanizing plants without fume collection equipment result in high corrosion rates, debris build...

KTE Updates – Zinc ready for melting

What does 720 tonnes of Zinc look like? 720 Tonne's of Zinc ready to be melted, reporting live data back to Melbourne for Kingfield technicians to control as this mega factory build continues.